The general introduction of Hot melt sealant machinery:

1) Different capacity design from 50L to 50,000L.

2) Made of stainless steel 304/316L, or other material (decide by client).

3) Have jacket and coil-pipe style.

4) Vacuum and high-pressure are available.

5) Super mixer for most chemicals/food materials mixing and reacting.

6) Widely used in producing resins, adhesives, paints, cosmetics, pharmaceuticals and other chemical productions.

7) Can be heated by oil or water or steam, temperature range: 0~500 centigrade.

8) With different mixing paddles, can be designed as requirements.

9) Supply whole production line for different products, also including producing technology.

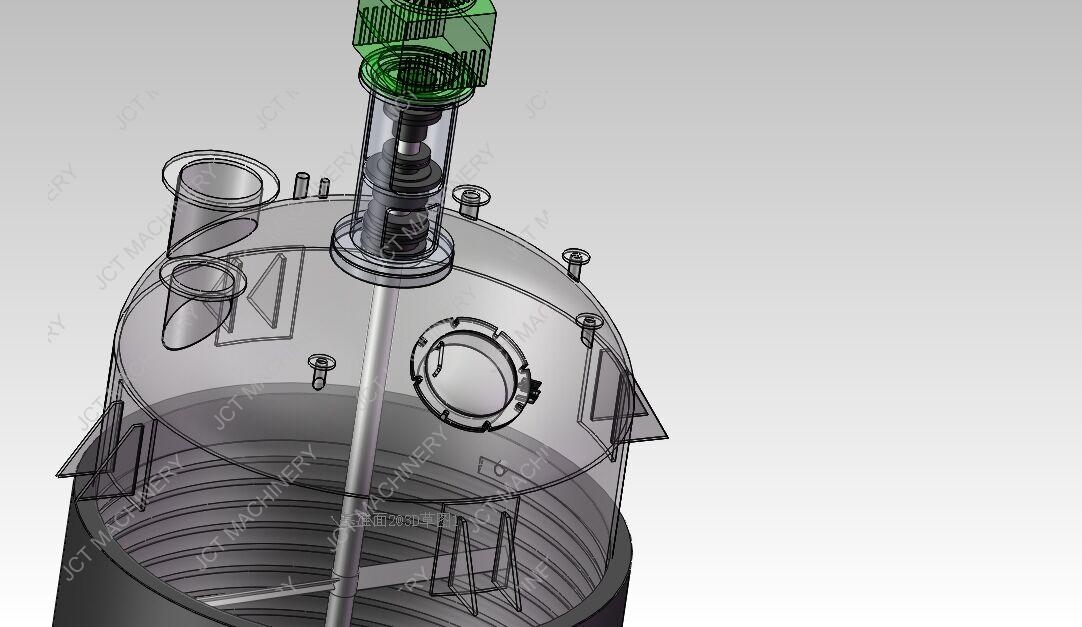

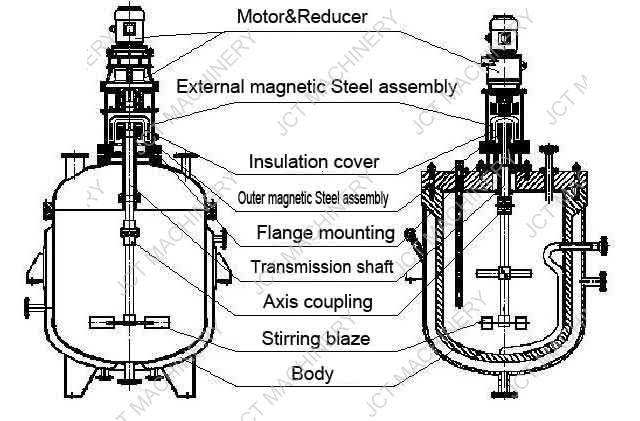

Hot melt sealant machinery is made up of body vessel, jacket vessel, gears, mixing devixes, heating devices, cooling devices, seal composition, etc.

The auxiliary equipment consists of Head tank, distillation column, condenser, water separator, collecting cans, dilution tank, filters, etc.

Hot melt sealant machinery is the main chemical react production equipment, which is widely used in resins, adhesives, paint, cosmetics, pharmaceutical and other chemical production.

Break down or Re-combined the molecule through mixing, Heating, cooling, Vacuumize, etc. Suit for polymerization, hydrogenation, vulcanization, nitration,etc

In addition, We can supply production line range of Hot melt sealant machinery:

1.Alkyd resin production line

2.Unsaturated resin production line

3.Acrylic resin production line

4.Urea-formaldehyde resin production line

5.Polyurethance resin prodcution line

6.Epoxy resin production line

7.Silicone sealant production line

8.White latex glue production line

9.Hot melt glue production line

10.Acrylic sealant production line

11.Paint production line

12. Super glue production line

13.Silicone rubber production line.

Hot melt sealant machinery applies for:

1). Resin:

Alkyd resin, epoxy resin, phenolic resin, acrylic resin...

2). Glue/ Adhesive:

Hot melt glue/ adhesive, grafted glue, white glue, silicone glue, all-purpose glue, PVC glue, PVA...

3). Others:

Paint, pigment, PVC, PVA, PVAC, PU, acrylic acid, and other latex, emulsion and liquid glue and adhesives.

Technical parameters of Hot melt sealant machinery:

|

Specifications

|

Effective volume (L)

|

Heating

|

Heating(colding) structure

|

Impeller structure

|

Shaft seals

|

Material within the cylinder

|

Remarks

|

|

FYF-50L

|

50

|

HTF

Electric heating

Steam

Hot water

|

Jacket

Outside the half-pipe

The coil

|

Oblique paddle

Anchor

Box

Turbo

Lo band

Impeller

Combined

|

Single mechanical seal

Double mechanical seal

Packing

|

304

321

316

Q235

|

1, the motor power size, stirring speed level determined according to actual requirements.

2, the thickness of the cylinder pressure to be based on response.

|

|

FYF-100L

|

100

|

|

FYF-200L

|

200

|

|

FYF-300L

|

300

|

|

FYF-500L

|

500

|

|

FYF-1000L

|

1000

|

|

FYF-1500L

|

1500

|

|

FYF-2000L

|

2000

|

|

FYF-2500L

|

2500

|

|

FYF-3000L

|

3000

|

|

FYF-4000L

|

4000

|

|

FYF-5000L

|

5000

|

|

FYF-6000L

|

6000

|

|

FYF-8000L

|

8000

|

|

FYF-10000L

|

10000

|

|

FYF-12000L

|

12000

|

|

FYF-16000L

|

16000

|

|

FYF-20000L

|

20000

|

|

FYF-25000L

|

25000

|

|

FYF-30000L

|

300000

|

Contact information:

If you need to know the detailed equipment configuration, production technology, production

process, please contact us.

Email:[email protected]

Mobile: 0086-181 3837 3963(WhatsApp, Wechat)

Address: Donglian Jincheng Industrial Zone, Danzao Town, Nanhai, Foshan, Guangdong, China.

Product line

Product line sigma mixer

sigma mixer mixing tank

mixing tank Ribbon blender

Ribbon blender kneading machine

kneading machine Reactors

Reactors High-Shear Mixers

High-Shear Mixers

CN

CN

HOME

HOME

Related Suggestion

Related Suggestion

Jul 25,2024

Jul 25,2024

Tel

Tel

Email

Email

Address

Address